SV 66

Where did continous improvement come from ?

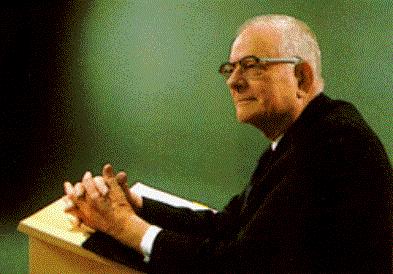

Dr. W. Edwards Deming was an eminent scholar and teacher

in American academia, he inspired and guided the spectacular rise

of Japanese industry after World War II, and the resurgence

of the American automobile industry in the late 1980s.

"The American guy who showed Japanese industry how to do Quality."

- Create and communicate to all employees a statement of the aims and purposes of the company.

- Adapt to the new philosophy of the day; industries and economics are always changing.

- Build quality into a product throughout production.

- End the practice of awarding business on the basis of price tag alone; instead, try a long-term relationship based on established loyalty and trust.

- Work to constantly improve quality and productivity.

- Institute on-the-job training.

- Teach and institute leadership to improve all job functions.

- Drive out fear; create trust.

- Strive to reduce intradepartmental conflicts.

- Eliminate exhortations for the work force; instead, focus on the system and morale.

- (a) Eliminate work standard quotas for production. Substitute

leadership methods for improvement.

(b) Eliminate MBO. Avoid numerical goals. Alternatively, learn the capabilities of processes, and how to improve them. - Remove barriers that rob people of pride of workmanship

- Educate with self-improvement programs.

- Include everyone in the company to accomplish the transformation.

The abbreviation MBO in point 11(b) above is taken to mean Management by Objectives (popularised by Peter Drucker)